Australia has the same issues as New Zealand but the size to solve them

10 June 2025

By Vegetables NZ communications manager, Andrew Bristol

The Australian vegetable sector has the same issues as New Zealand’s but the size – sector and individual business size – to solve them.

That’s my conclusion after spending five days in Queensland, as part of Vegetables NZ’s Brisbane tour of learning.

Every Australian grower we met talked about the challenges of growing the best crop possible, responding to changing consumer preferences, and staying in business – and in that order. They were all upbeat about their businesses’ future but knew they would have to adapt – just like they’ve always had to adapt.

Each growers’ knowledge and passion for the crop – built up over generations in all cases – was tangible. Each grower shared an incredible amount of practical knowledge, honed through a trial-and-error approach that appeared to be made possible because the businesses are big, and grow in different states, down the east coast of Australia and sometimes, in Tasmania. Each grower was quick to point out, however, that what works in one state usually doesn’t work in another, let alone in the paddock down the road.

The tour spent the first two days in and around Gatton, which is inland from Brisbane, before returning to Brisbane for Hort Connections – which attracted more than 4000 delegates and more than 200 trade exhibitors from across the Australian vegetable, fruit, nut and flower sector.

The tour joked that Gatton is the Pukekohe of Queensland. In the area, we visited three large growing operations: the Mulgowie Farming Company, Koala Farms and Kalfresh Vegetables. All three businesses are vertically integrated with packhouses, and Koala Farms also has its own nursery – because they are big enough to do so and want the control.

We also visited the Queensland Department of Agriculture and Fisheries’ Gatton research station; and Metagen, a biostimulant producing business.

Common focus: soil and plant health

All three growing operations had in common a focus on soil health and their growing having as little impact as possible.

Mulgowie grows sweetcorn and green beans. Sustainable agriculture manager, Andrew Johanson talked about ‘learning how to do things without chemistry’ since the mid-90s, when agchem resistance in the area first became rife. Andrew’s mantra is ‘healthy soil, healthy plants and healthy people’. He’s a big fan of as little tillage as possible and likes to ‘keeping living roots in the ground’ for as long as he can, to optimise nitrogen.

Andrew testing in the field. Joe Balle looks on

Andrew’s growing is all evidence based. For example, he outlined how they have been able to increase their sweetcorn yield by 11% by using buckwheat as a cover crop. What’s more, by using no till or little till, they have been able to reduce their fuel costs by 43% because the tractors are doing less work. However, because the cost of fuel has gone up so much, they are spending the same amount of money.

Andrew’s colleague, Steve Martin, spoke even more passionately than Andrew at times. Steve talked about how their growing methods result in far healthier plants, with higher brix that ‘taste better and last longer in the fridge’. Steve’s vision is that one day, vegetable growers like Mulgowie will be able to make nutrient claims in marketing.

At Koala Farms, we were welcomed by founder, Anthony Staatz who said they were a ‘very open book sort of business. This doesn’t mean that what we do is the best, but it works for us and there’s much more value in people sharing.’

Anthony Staatz

Anthony, his son Nick, and nursery manager, Rohan Bonnell talked candidly about their business, and their trial-and-error approach – in the nursery and in the field. Koala Farms grows all sorts of lettuce, broccoli, cucumbers and spinach, between states so they can supply the chain stores (through a third party, which is rare in Australia) 365 days a year.

Like Mulgowie, Koala Farms practices a minimum till approach to growing and is very focused on soil health. They also rotate their crops constantly, which is helped by their size.

Kaifresh grows and packs carrots (May-January), onions (October-December), snacking capsicums and beans, which they even export to New Zealand. They also have a sideline in organic beans, corn and baby watermelon.

Craig Dingle

Head of agriculture, Craig Dingle – who just happened to be named the 2025 Corteva Agriscience Young Grower of the Year later in the week at the Hort Connections gala dinner – said Kalfresh aims to ‘sell everything we grow’. This objective was very apparent in the carrot packing shed, where they process and pack their carrots in many different ways, from whole to ‘coins’, in response to consumer demand.

Craig said whereas there used to be 32 carrot packing sheds in the area 30 years ago, today there are just two. However, Kaifresh does pack for other carrot growers.

In the field, Craig and farm manager, Angus Stainlay, again spoke candidly about the challenges of growing – rising labour, fertiliser and agchem costs – and keeping up with consumer preferences, in the packhouse.

Kaifresh is experimenting with robotics in the field, namely a solar powered FarmDroid autonomous seeder and weeder. Craig said using the latest technology makes sense for them because of their size and rising labour costs.

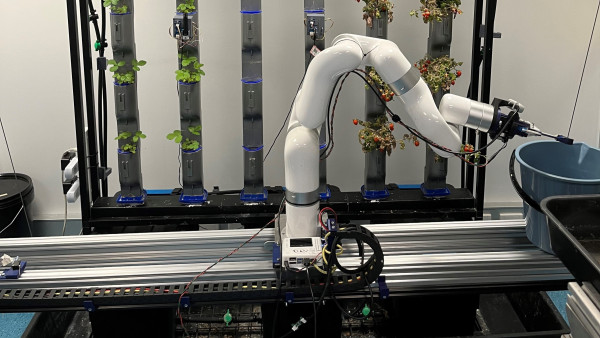

Robotics in action

The tour team at the research farm in Gatton

At the Gatton research station, we saw demonstrated – albeit in the car park as the ground was too wet – the ecorobotix ARA, ultra-high precision robotic weed sprayer (pictured at the start of this story). This sprayer reduces agchem use by up to 95% by only spraying the weeds, as it can distinguish between the weeds and the crop. It can work in the middle of the night and sprays 4ha an hour.

The sprayer was at the research station as part of Queensland’s VegMech initiative, which is billed as ‘Technologies for next-gen vegetables systems’. The three-year initiative is funded by growers (that is, levies) through the Hort Innovation Vegetable Fund and the Queensland Government.

The initiative targets ‘tech’ that is on farm (that is, commercially available) or about to go on farm. The objective is to help growers implement new technology, as often, there’s a gap between what it says on the box and how it works in the field.

That said, James Terry, co-founder of CloudFarming, said most growers would be able to set up the FarmDroid, which he is using to seed and weed broccoli.

‘The FarmDroid just makes life better. My yields have gone up while my chemical use has gone down. I plan to be planting all my broccoli using the FarmDroid within the next two years, as I build up knowledge.’

James was a speaker at the Annual Vegetable Industry Seminar, held back in Brisbane before the official opening of Hort Connections.

James grows on 170ha in Tasmania. While the FarmDroid moves at only 900m an hour – or less, James said this did not matter, as the FarmDroid can work into the night, makes three goes to try and fix itself, and is just a lot more efficient and effective than traditional seeding and weeding methods.

Obviously with new technology, return on investment is key. But it would appear that in Australia, thanks to scale, is as quick as one to two years. The other point that James made was that with technology changing so fast, the machinery that growers buy today needs to be able to be adapted to use any new technology.

The trade exhibition as part of Hort Connections was full of new technology (including some very impressive tractors) and companies selling biostimulants. Tour sponsors, Fruitfed and Valagro + Syngenta Biologicals, told the tour the value of the biostimulant industry is currently around US$4bn and expected to reach US$9.75bn by 2032.

Biostimulants along with robotics are part of the drive to use fewer agrichemicals by improving ‘natural’ soil and plant health, while increasing yields. Biostimulants and robotics are where growing, white coats and laboratories come together. The tour was fortunate to go behind the scenes at the Queensland University of Technology (QUT), to see some of the research being done on plants (including genetic modified organisms) as well as the university’s robotics development laboratory.

Robotic tomato picker under development

QUT’s campus and facilities are outstanding, and we were made to feel very welcome – just like we were everywhere else we went. QUT is right in the city centre, by the river, and the Brisbane Convention and Exhibition Centre is just across one of the many bridges, on the other side of the river.

But there’s a but in all this

But what if people continue to eat fewer vegetables? In Australia, exhaustive research has shown that Australians only eat 1.8 servings of vegetables a day. That is about the size of a medium apple.

Justine Coates is the managing director of Plus One Serve of vegetables. She spoke with passion about Australia’s government, industry, health and retail sectors’ multi-faceted behaviour change programme, to get Australians to add one more serve of vegetables (half a medium apple) to their diet a day.

The return on investment on this six-year programme is outstanding: A$12.30 for every A$1.00 invested, with 85% of the total return going to growers, which is equally amazing. What’s more, the extensive research that informs this programme says that increasing consumption by 58% - which is what adding one more serve represents – is achievable. The programme will provide A$3.3bn in economic benefits and reduce health care costs by $1.38bn, providing a whooping A$4.68bn in total benefits.

No wonder everybody in Australia – government, industry and retail – has got in behind this campaign. Vegetables NZ is currently liaising with Justine and Plus One Serve because we believe the programme could be applied in New Zealand. Watch this space…

Vegetables NZ would like to thank all the Australian hosts, and acknowledge the support of all the tour’s sponsors: Fruitfed, Valagro+Syngenta, and the Vegetable Industry Centre of Excellence (VICE).